Shurflo Liquid Pump Schematic – Parts Supply for Installations

Improper installation of Water Pump systems can significantly reduce their effectiveness by up to 30%. It’s crucial to comprehend the mechanics of the Shurflo Pump schematic for maximum efficiency and durability. Each part within the schematic serves an essential purpose in the Pump operation. We’ll dive into the importance of grasping these Shurflo 8000 parts, utilizing the diagram to show their setup and how they function collectively.

Parts Supply for Installations is your preferred provider for every Shurflo Water Pump component essential for assembly and servicing. Utilizing the Shurflo Water Pump parts schematic enables users to expertly handle installation and servicing. This base helps in forming wise selections for the optimal and reliable performance of their water pumps.

Comprehending Shurflo Pump Systems

Shurflo Water Pumps are at the nexus of ingenuity and functionality, fulfilling the requirements of diverse applications. This portion seeks to provide an in-depth overview of Shurflo Pump models, their distinct functions, and the merits of selecting these pumps. They are famed for their technological sophistication and efficiency.

Overview of Shurflo Pump Types

Shurflo’s line-up features Pump models like the membrane and farm series, engineered to meet varied demands. The membrane models are praised for their robust build and efficiency in moving liquids. Notable examples include the 2088-343-135 and 2088-343-500 deliver robust performance with notable flow and pressure ratings.

The agricultural series, alternatively, is built for effective fluid transport in farming environments.

Applications of Shurflo Pumps

The flexibility of Shurflo Pumps enables their use in a diversity of settings. They are typically utilized for:

- Agriculture: Delivers options for irrigation and liquid fertilization.

- Motorhomes: Maintains a steady water flow with regulated pressure settings.

- Household: Well-suited for yard upkeep and home Water Pump installations.

This flexibility enables these pumps to integrate smoothly into various setups, showing their adaptable nature.

Merits of Choosing Shurflo Pumps

Opting for Shurflo Pumps brings several benefits. Their automatic priming function removes the hassle of hand priming. They also have resilience to chemicals, ensuring longevity in harsh environments. Readily available Shurflo diaphragm Water Pump parts facilitates maintenance, boosting service life while minimizing interruptions. Other benefits of Shurflo Pump systems consist of:

- Consistent operation with customizable pressure settings.

- Effortless assembly with catalog guidance.

- Diverse pump fittings for seamless integration with existing setups.

With these characteristics, Shurflo Pump systems promise consistent performance and dependability. They guarantee ongoing functionality, assuring users of reliable operation.

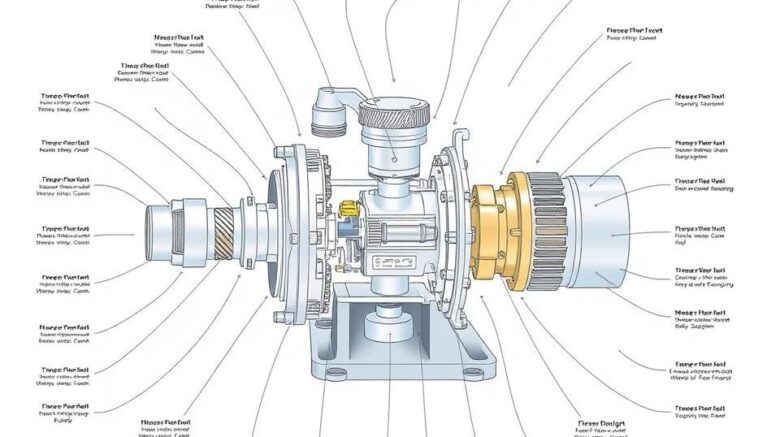

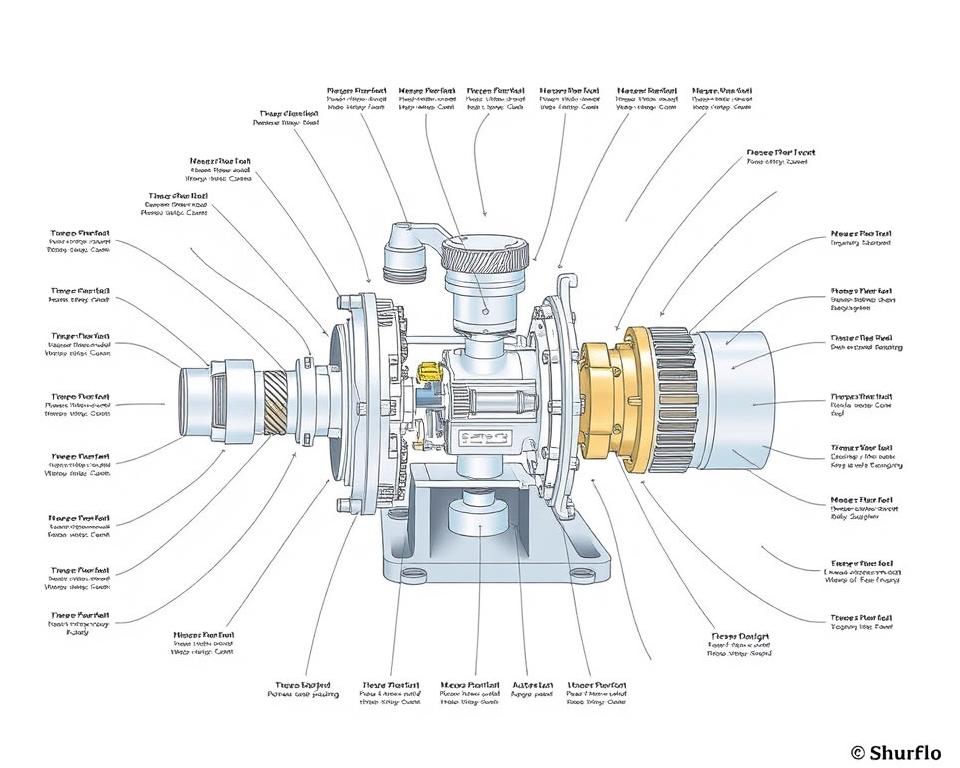

Shurflo Water Pump Diagram and Its Importance

The Shurflo Pump diagram is essential for understanding its parts and workings. By studying the Shurflo Water Pump schematic, users can assemble, troubleshoot, and preserve optimal performance. This schematic is crucial for identifying the required Shurflo Pump parts. Accurate assembly guided by the schematic ensures peak performance.

Essential Elements in the Diagram

The Shurflo Water Pump schematic showcases essential components necessary for proper operation:

- Motor: The engine, the central unit of the Pump, powers the impeller, enabling flows from 41 to 168 GPM.

- Diaphragm: Assists in maintaining uniform flow and pressure.

- Check Valves: Key to stopping reverse circulation, these devices secure that water moves correctly.

- Casing: With a maximum pressure of 200 PSI, the housing maintains structural integrity.

Interpreting the Shurflo Pump Schematic

To analyze the Shurflo Pump diagram, one must note distinct symbols and markings:

- Study the layout of parts shown in the schematic.

- Recognize the indicated flow path via directional arrows.

- Examine the remarks for information on wiring dimensions and mounting configurations.

Understanding this schematic is vital for efficient construction, servicing, and determining required elements.

Fitting Shurflo Water Pumps

Setting up a Shurflo Water Pump can make any water system more functional. Knowing the necessary steps and components is crucial for a successful setup. This tutorial covers vital steps and the tools needed for a triumphant installation.

Installation Procedure for a Shurflo Pump

- Begin by gathering all tools for shurflo pump installation. Verify that you have an appropriate screwdriver, a wrench, and a 50-mesh strainer.

- Attach the 50-mesh strainer to the inlet of the Pump. It is advisable to employ a pliant hose for connecting the inlet to lessen connector stress.

- Apply a 1/2” to 3/8” barb splicer for connecting tubing securely. To avoid leaks, opt for reinforced tubing with Oetiker clamps.

- The pump should be wired to a properly grounded outlet. A certified electrician is recommended for this task to adhere to local codes.

- Charge the accumulator tank with 50 PSI of clean air or nitrogen. This is important for the best pressure performance.

- Place a SHURflo 65 psi water pressure reducer valve at the inlet to maintain appropriate pressure conditions.

- Wrap up the setup by connecting all components. Don’t exceed the motor’s amperage rating; thermal breakers offer extra safety.

- Test the system and check the pressure switch’s functionality.

Installation Essentials: Tools and Parts

| Item | Information |

|---|---|

| 50-mesh strainer | Removes contaminants at the inlet for superior operation. |

| Pliable hose | Ideal for connecting the inlet, lessening stress on attachments. |

| Tubing splicer | Provides a secure 1/2” to 3/8” tubing linkage. |

| Storage tank | Inflated to 50 PSI to uphold system pressure. |

| Switch | Regulates operation by monitoring pressure conditions. |

| Electrical equipment | Required for safe connections, ensure compliance with local electrical codes. |

| 65 psi SHURflo valve | Lowers incoming water pressure to stabilize Pump function. |

Troubleshooting Common Issues with Shurflo Pumps

Mastering issue resolution for Shurflo Pumps boosts overall efficiency. This part provides a troubleshooting guide. It helps users diagnose and resolve frequent problems to secure continuous performance. Problems related to operation, flow, and acoustics are addressed with effective fixes.

Typical Issues and Remedies

Varying scenarios lead to issues with Shurflo pumps. Here is a list of frequent problems with corresponding remedies:

- Pump runs but no water flow: Assess the water supply level, inspect piping for clogs or impairments, ensure adequate priming, and test Pump performance.

- Pump won’t turn on after winterization: Review proper winterization procedures, ensure all valves are open, verify electrical connections, and inspect for potential damage to components.

- Pump cycling on and off: Inspect for leaks, check for air in the system, ensure appropriate pressure settings, and verify the functionality of the pump and pressure switch.

- Noisy pump: Inspect for loose connections, add padding under the pump, insulate water pipes, and ensure proper installation of the unit.

Troubleshooting Manual for Shurflo Pumps

A comprehensive Shurflo Water Pump troubleshooting guide aids in swift diagnosis. Presented here is a table outlining frequent faults and their remedies:

| Frequent Problem | Potential Causes | Solutions |

|---|---|---|

| Pump runs but no water flow | Deficient water supply, clogs, incorrect priming | Check tank level, inspect water line, verify pump function |

| Failure to start | Incorrect winter procedures, blocked valves, wiring faults | Reassess winter steps, ensure valves are open, verify wiring |

| Pump cycles on and off | Leaks, air in system, pressure issues | Examine for leakages, eliminate air, modify pressure controls |

| Noisy pump | Loose connections, inadequate installation | Tighten connections, add padding, insulate pipes |

Grasping the shurflo pump exploded view enables users to locate malfunctioning components is essential for accurate diagnosis. Adhering to these guidelines ensures pump maintenance and reliable operation.

To Conclude

Understanding the Shurflo Water Pump schematic is vital for achieving maximum Pump efficiency.

Used in diverse environments including RVs and farming, a precise setup is imperative for consistent performance.

Familiarity with the diagram’s elements allows for efficient installation and sustained maintenance.

Installation Parts Supply is paramount for obtaining all needed Shurflo pump parts and services, offering comprehensive support, ensuring access to essential tools and components. Such support guarantees proper assembly. Through correct installation practices and proper maintenance of elements such as the strainer, Pump durability and performance are improved.

This write-up provides the insights needed to enhance overall Shurflo system operation. By taking advantage of Shurflo pumps and implementing installation tips, users are prepared to face any challenges with assurance.